Wholesale Dealers of Ball Mill – Ball Mill – Mets

Wholesale Dealers of Ball Mill – Ball Mill – Mets Detail:

Product description

The ball mill consists of the feeding part, the feeding part, the rotating part, the transmission part (the reducer, the small transmission gear, the motor, the electric control) and so on. The hollow shaft is made of cast steel, the lining can be changed, and the rotary gear is made of the rolling teeth of the castings. The barrel has a wear-resisting lining board, which has good wear resistance. The machine is stable and reliable.Ball mill host including cylinder, cylinder body with useful lining made of wear resistant material, have and maintain its rotating cylinder bearing bearing, have driven part, such as motor, and the drive gear, pulley, triangle, etc.

About called blade parts, generally not main components, components on the feed end inlet with internal screw them spiral blade, can be said on the discharge end parts discharging mouth with internal screw can call them spiral blade.

In addition, in the auxiliary equipment of the discharging end, if the spiral conveyor is used, there will be parts called spiral blades in the equipment, but strictly speaking, it is not a part of the ball mill. Dry ball mill and wet grate ball mill can be selected according to material and drainage mode. Energy saving ball mill, the automatic aligning double row centripetal spherical roller bearing, the running resistance is small, the energy saving effect is remarkable. The barrel body part of the original barrel has been added a cone cylinder, which increases the effective volume of the mill and makes the distribution of medium in the tube more reasonable. This product is widely used in non-ferrous metal, ferrous metal, non – metal beneficiation field, chemical industry and building materials industry.

About installation

Ball mill installation:

A) the installation plan is designed according to the user’s basic engineering and should be installed in the direction,location and space of the diagram;

B) the lower plane of the fuselage should be solid, and the flatness of the bottom plane of the cylinder is not greater than 1.5/1000 after the horizontal adjustment.

1.Install:

A) remove the material from the base of the installation equipment, especially the inner wall of the hole should not have dust, oil, water and other liquids;

B) after unpacking the packing cases, the main engine shall be moved to the installation position with appropriate lifting facilities (crane/forklift);

C) put the equipment in position, anchor bolt mounting holes, and the “living feet” of the random belt shall be welded to the chassis of the frame after being welded onto the chassis of the frame, then the secondary grouting can be made;

D) after installation of 24 hours of cement strength, it can be used to tighten the nut loading test machine;

E) access to power;

F) installation inspection and correction of discomfort;

G) electric cabinets are placed in the auxiliary engine room without the need to install floor.

2. Test operation:

Ball mill installation is complete, the inspection, can be empty test run, commissioning of ball mill by skillful ball mill operators should be responsible for, ball mill and strictly abide by the safety operation procedures.

(1) the running time of the idle operation shall not be less than 12-24 hours, and the problems in operation shall be solved in time.

(2) the idle running of commissioning to normal load test run, can be carried out when the load test run in every phases, load operation should be performed according to the condition of discharge in the feed, avoid unnecessary grinding ball and the cylinder liner and damage.

A) add the appropriate materials and 1/3 of the steel balls (the maximum weight of the ball mill) to try for 12 to 24 hours.

B) add up to 2/3 of the amount of steel balls to run for 24 to 48 hours.

C) according to the ball mill discharge conditions, production of qualified products, with reference to the same kind of ball-mill machine actual loading quantity, determine the ball loading quantity of the ball mill machine, for not less than 72 hours test run.

(3) the increase of the above load and the length of the test run time are determined based on the running conditions of the gear of the size gear and reducer gear (temperature rise, noise, tooth surface contact, etc.). Before the contact accuracy of the tooth surface does not meet the design requirements, it shall not operate at full capacity.

(4) the cooling and lubricating system should work normally in the test operation, and the temperature of main bearing, transmission bearing and reducer should be normal.

(5) after loading 2/3 of the steel ball test for 24 to 48 hours, check and tighten all the bolts again.

(6) the trial operation must be carefully recorded.

Mixing, grinding, ball mill is mainly used for ceramic materials is a necessary equipment for the production of various kinds of ceramic products, the machine USES the coupling stress, reduce the starting current, its structure is divided into integral and detached. With a v-belt drive, single-stage or double deceleration, equipped with an independent small power motor.

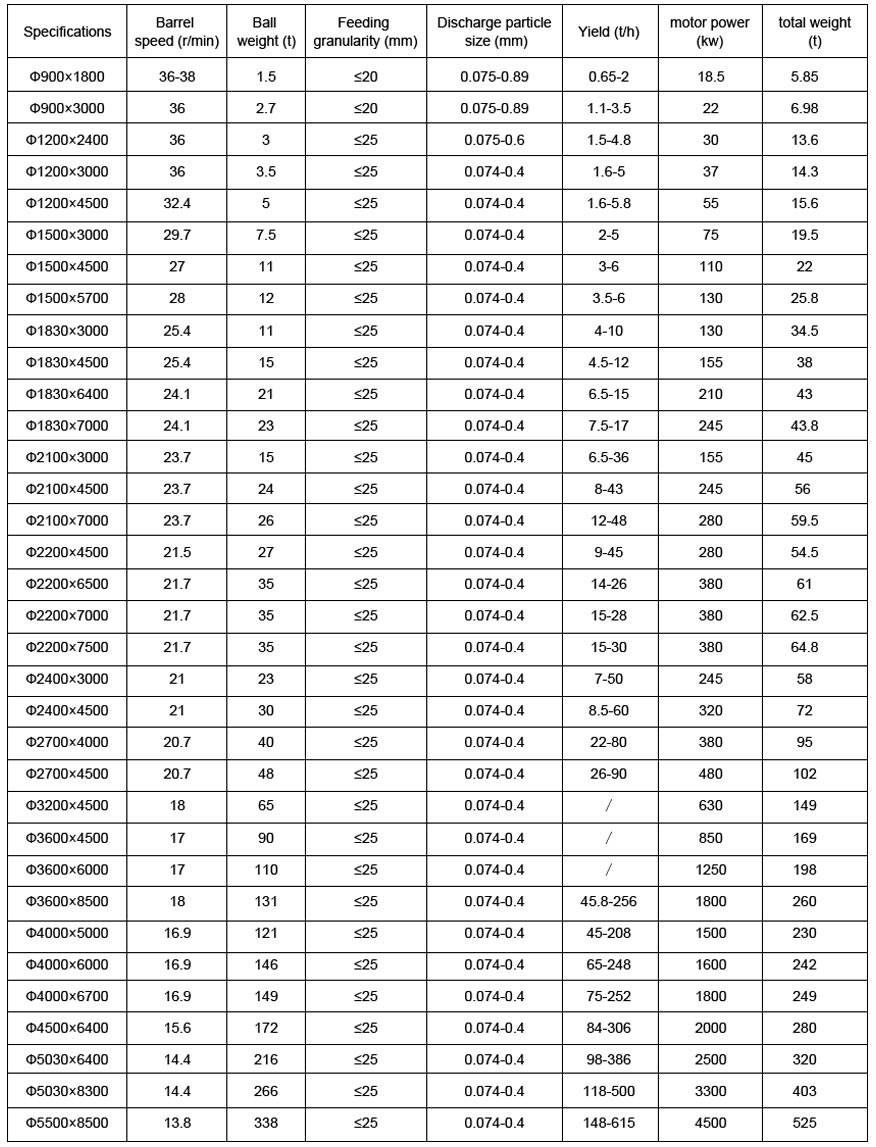

Performance data

Product detail pictures:

Related Product Guide:

Our goods are broadly recognized and reliable by users and can meet consistently switching financial and social demands of Wholesale Dealers of Ball Mill – Ball Mill – Mets, The product will supply to all over the world, such as: Thailand, Denver, Sacramento, During the 10 years of operating, our company always try our best to bring consumption satisfaction for user, built a brand name for ourselves and a solid position in the international market with major partners come from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. Last but not least, price of our products are very suitable and have fairly high competition with other companies.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.